PA / EM Oddities

![]() This page is compatible with Klipper, Marlin, and RepRapFirmware.

This page is compatible with Klipper, Marlin, and RepRapFirmware.

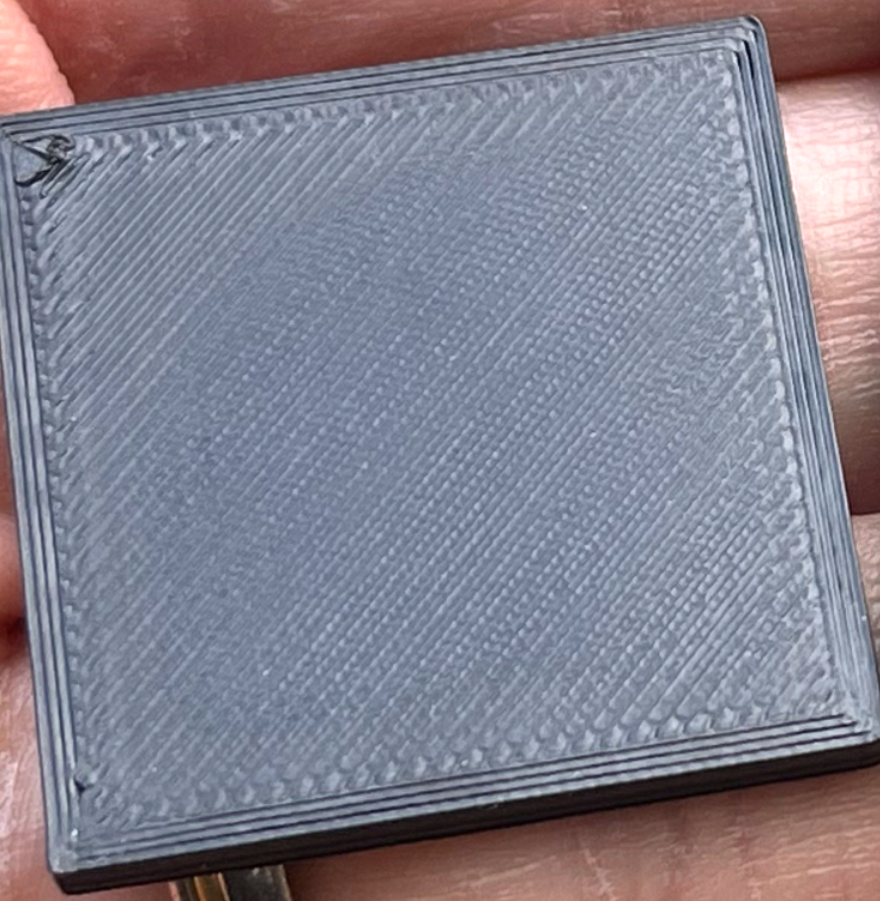

Slight Perimeter Gapping

Some find that after tuning PA and EM, minor perimeter gapping is still present:

Assuming EM is well tuned, this is often caused by a slight ![]() flow dropoff at higher print speeds — since most people print their perimeters faster than their top layer.

flow dropoff at higher print speeds — since most people print their perimeters faster than their top layer.

There are a few different things you can try:

(in order of my preference)

- Ensure that you are not

outrunning your hotend and that you do not have a partial nozzle clog.

outrunning your hotend and that you do not have a partial nozzle clog. - Take measures to improve your hotend’s max flow rates.

-

Higher flow ceilings allow for better extrusion consistency at lower flow rates, as the

flow dropoff curve starts later. It is beneficial for extrusion consistency at different speeds, even when you don’t intend to use the full flow rate.

flow dropoff curve starts later. It is beneficial for extrusion consistency at different speeds, even when you don’t intend to use the full flow rate.

- Try increasing hotend temperatures a bit.

- Temperature can have a significant effect on max flow rates.

- Note: temp changes can have a minor effect on PA values.

- Use a hotend and/or nozzle with a higher flow ceiling.

-

Bondtech CHT and

Bondtech CHT and  Bozzle both provide a sizeable flow rate increase to any hotend that supports V6 nozzles. CHT also has a Volcano variant.

Bozzle both provide a sizeable flow rate increase to any hotend that supports V6 nozzles. CHT also has a Volcano variant.

-

- These steps can reduce the effect, but may not 100% fix it.

-

Higher flow ceilings allow for better extrusion consistency at lower flow rates, as the

- Increase your EM until the gaps disappear. Then, lower your top layer flow (

fill_top_flow_ratioin SS) until your top surfaces look perfect again. - Follow my

“determining maximum volumetric flow rate” instructions, and choose the “conservative” (always-100mm) value to enter into your slicer (PS/SS).

“determining maximum volumetric flow rate” instructions, and choose the “conservative” (always-100mm) value to enter into your slicer (PS/SS). - Slow your perimeters down. The faster you print, the greater this flow dropoff becomes.