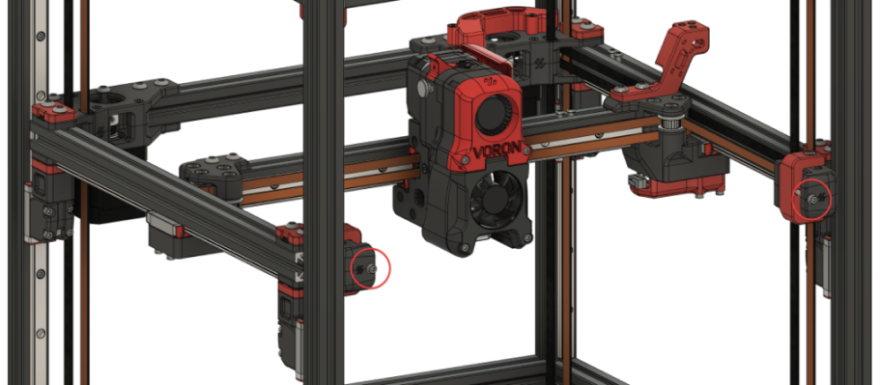

Voron V2 Gantry Squaring

Poor gantry squaring can cause a number of problems, such as:

- First Layer issues

- Z belts rubbing against the gantry’s printed parts

- X axis to be “racked” at the front but not the back (or vice versa)

Steps 14-16 of the instructions below can also help with gantry stability.

Demonstration

Watch this video.

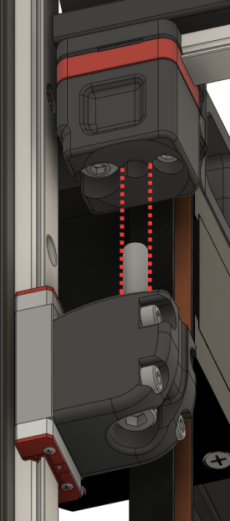

Notice that the idlers get “pinched” when moving the X extrusion back/forth (this is shown with loose Z joints).

Method

![]() Some have found

Some have found ![]() Z Locks to be useful for this procedure. They are not required, however.

Z Locks to be useful for this procedure. They are not required, however.

- Enter this g-code:

SET_IDLE_TIMEOUT TIMEOUT=99999- This arbitrarily high timeout just gives us time to work. We need the Z motors to be energized and holding for the whole process.

-

G28, thenQUAD_GANTRY_LEVEL. - Jog your gantry to the center of the build volume using the LCD or web interface.

- This will give you space to work. You need easy access to both the bottom and top of your gantry.

- Turn off ONLY your A/B motors using these g-codes:

SET_STEPPER_ENABLE STEPPER=stepper_x ENABLE=0SET_STEPPER_ENABLE STEPPER=stepper_y ENABLE=0

- Loosen your A/B belt tension fully.

-

Take off your side panels.

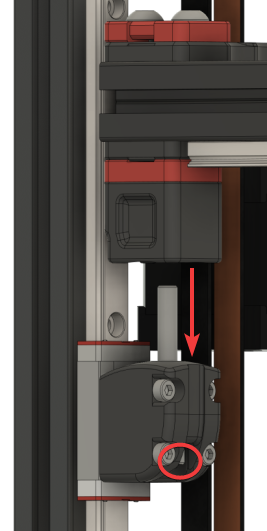

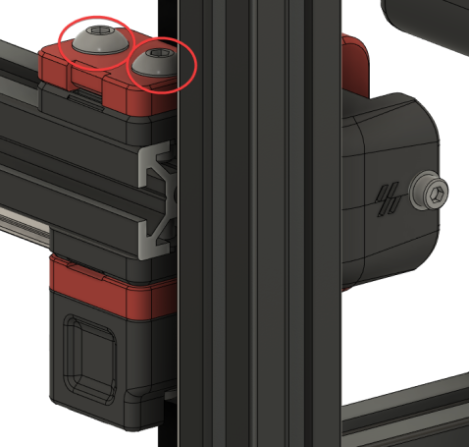

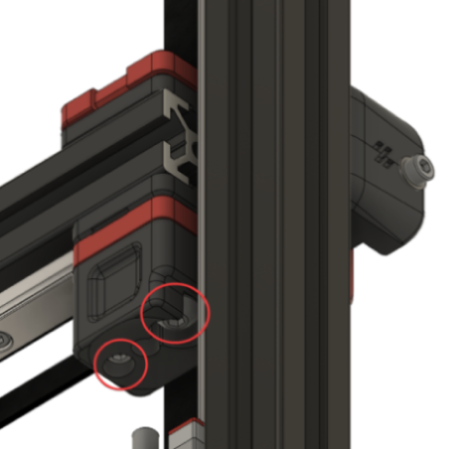

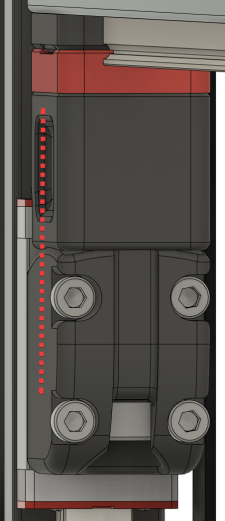

- Unscrew and drop your lower Z joints.

-

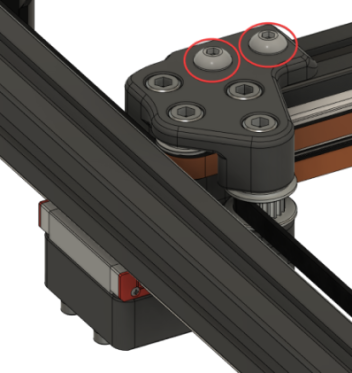

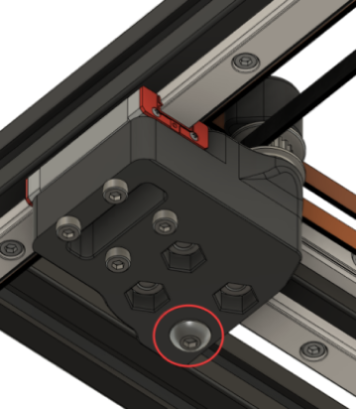

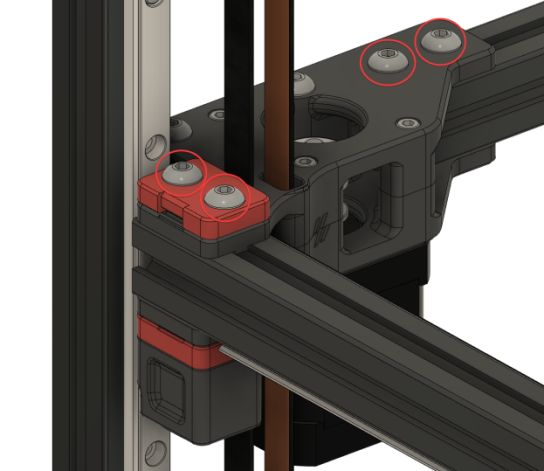

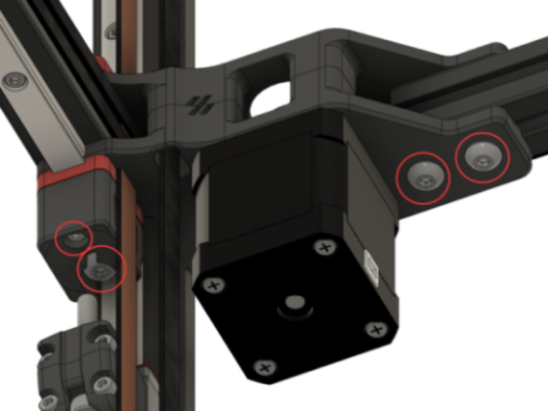

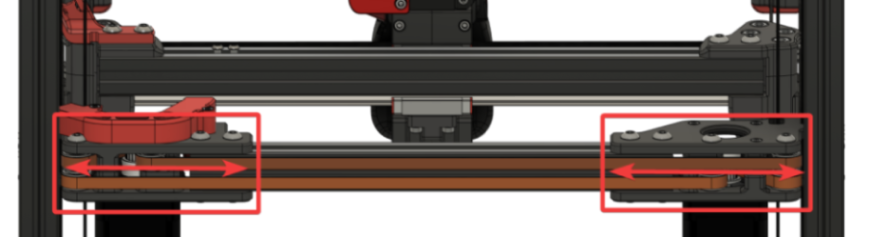

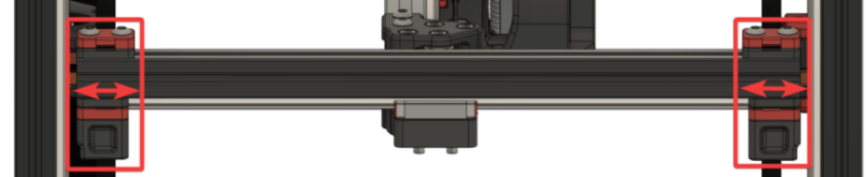

PARTIALLY loosen all connections to the extrusions.

- You need all of these bolts to be loose enough to freely adjust against the printed part on the extrusions.

Where there are Z belt clamps, ensure that you do not loosen the bolts so much that the Z belts release. Only loosen enough to allow for adjustments.

- And now, what we have been preparing for.

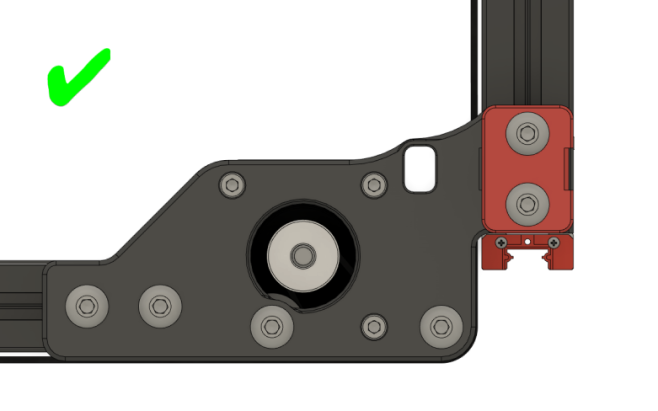

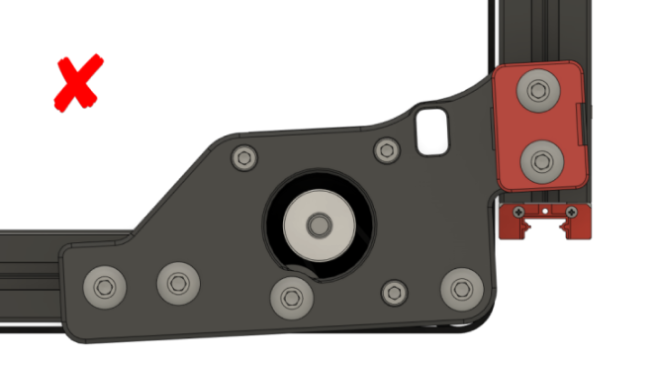

Adjust your gantry so that it sits perfectly on top of the lower Z joints.- This involves moving gantry components further apart or closer together along the extrusions:

- Your gantry should align so that:

- Ensure that you do not inadvertently rotate your A/B joints during this process.

- Tighten every extrusion bolt again, except those in the X/Y joints. (you will tighten those during step 12)

- Ensure that your Z joints still align properly. Sometimes tightening can move things around.

- Re-install your lower Z joints and lightly tighten the M5 bolts.

- Don’t fully tighten them down yet - just lightly. The joint should still be able to articulate freely.

- Follow

Nero’s de-racking video.

Nero’s de-racking video. - Make sure to come back here afterwards! The following steps are still important.

-

Re-tension your A/B belts (to 110hz over a 15cm span).

Re-tension your A/B belts (to 110hz over a 15cm span). -

Reinstall your panels and fully heatsoak your printer for 1½ - 2 hours minimum.

-

QUAD_GANTRY_LEVEL3-5 times to “settle in” the gantry (and level it for the next step).- If you are getting new tolerance / retry errors, you may have left your Z joints a bit too loose. Try tightening them up just a bit more.

- Open the front door and fully tighten the M5 bolts in your Z joints while it’s still hot.

- This does two things:

- Somewhat “locks in” your QGL at its state in full thermal expansion.

- This can help with first layer issues.

-

Stabilizes your gantry.

-

If you have your Z joints too loose, you might notice that your gantry displaces back & forth a bit while printing.

-

This can help with ringing and layer consistency.

-

- Somewhat “locks in” your QGL at its state in full thermal expansion.

- This does two things:

-

RESTARTto reset your idle timeout.