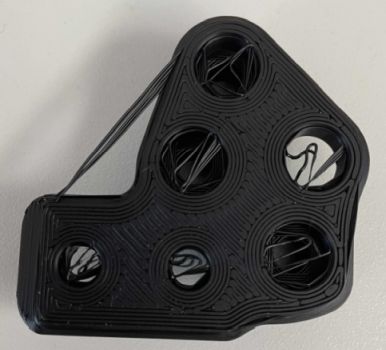

Perimeter Separation

![]() This page is compatible with all printers.

This page is compatible with all printers.

Table of contents

Adapted from ![]() bythorsthunder’s Discord pin. Thanks!

bythorsthunder’s Discord pin. Thanks!

If It Happens Primarily on Lower Layers

-

Ensure you have enough first layer squish. See

here.

here. -

Check your elephant’s foot / first layer compensation settings.

-

Reduce the amount, disable it, or fade it (SS only).

-

Having this set too high (especially when combined with bottom chamfers) can cause perimeters to print over nothing.

-

SuperSlicer: “XY first layer compensation” (

first_layer_size_compensation)- You can also increase

first_layer_size_compensation_layers, which gradually fades the compensation out over X number of layers.

- You can also increase

-

Prusa Slicer: “Elephant foot compensation” (

elefant_foot_compensation- yes it’s misspelled) - Cura: “Initial layer horizontal expansion”

-

If It Happens Everywhere

-

Make sure your external perimeter line width is wide enough.

-

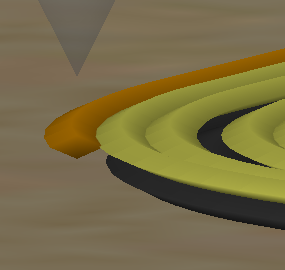

See

Stepover for a link to a great visualization by Maker’s Muse. A good stepover can greatly help with giving your perimeters more surface area to grab onto each other.

Stepover for a link to a great visualization by Maker’s Muse. A good stepover can greatly help with giving your perimeters more surface area to grab onto each other. -

Especially if you are using a layer height greater than 50% of your nozzle diameter. 100% line widths do not work well when exceeding 50% layer height.

- For example (with a 0.4m nozzle), imagine an extrusion line of 0.3mm height and 0.4mm width. You’re basically printing sausages! (Again, see the stepover link above)

-

-

Verify your extrusion multiplier. There should be no gaps or holes in top solid surfaces. See

here.

here. -

Try decreasing your perimeter speed.

-

If it only affects holes, you can slow them down in PS/SS by lowering

small_perimeter_speed.- In SS, you can configure small perimeter size thresholds using

small_perimeter_min_length/small_perimeter_max_length.

- In SS, you can configure small perimeter size thresholds using

-

Use the speed preview to ensure that it’s activating where you want it to.

-

-

Try increasing your hotend temperature. This helps with layer bonding strength.

- High speed printing often needs a temperature bump. ABS is usually in the 240-255 range.