VFAs (Vertical Fine Artifacts)

![]() This page is tailored for Voron printers.

This page is tailored for Voron printers.

Table of contents

VFAs With ~2mm Spacing

If the marks are about 2mm apart, that usually means that it’s coming from belt/pulley/idler teeth somewhere.

Ensure that these artifacts are still perfectly vertical even when printing irregularly shaped objects like the “rectangular 2 recommended.stl” object ![]() here.

here.

If they are not vertical (i.e. wood grain, diagonal, etc), see ![]() this article instead.

this article instead.

Print a square object at 45 degrees and see if it appears A, B, or both. This will tell you which axis/axes to look at.

- Your belts may be too tight.

Your A/B belts should be about 110Hz over a 150mm length.

Your A/B belts should be about 110Hz over a 150mm length. - Don’t miss the video link in page linked above.

- Apps:

- Android: Gates Carbon Drive (select “motorcyle” option) or Spectroid.

- iPhone: Gates Carbon Drive (select “motorcyle” option) or Sound Spectrum Analysis.

- Your belts may be rubbing a flange somewhere.

- It’s nearly impossible to have them all running dead-center, but you can look around for belt wear and belt dust to find where it may be rubbing too much.

-

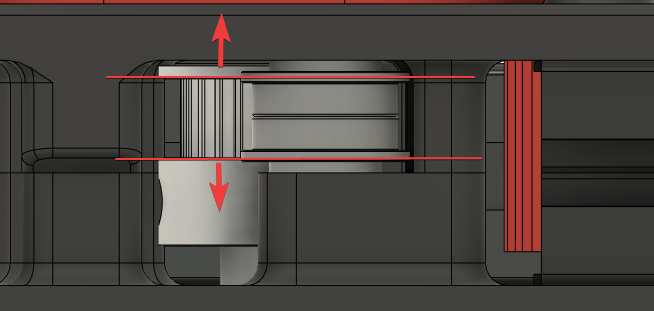

Ensure your motor pulleys are not positioned too high or too low. Ensure they all align with the belt paths:

- For V2, follow my

V2 gantry squaring instructions. A poorly squared gantry can be the root cause of a lot of alignment issues.

V2 gantry squaring instructions. A poorly squared gantry can be the root cause of a lot of alignment issues. - On all CoreXY printers:

de-rack.

de-rack. - For V2, this is part of the gantry squaring instructions above. Please follow those first/instead.

- Ensure that your pulleys, idlers, and extruder gears/idlers are all clean. Debris can accumulate and compress in the teeth.

- You may have poor quality belts. Only use genuine Gates brand belts.

- You may have poor quality motor pulleys and idlers.

- I, and a few others, have had improvements from switching to authentic Gates brand pulleys and idlers. They are more expensive, but are worth it in my opinion.

- On v2 at least, you only need them for A/B motors and X/Y idlers. Don’t waste the money on Z.

- US source:

- For idlers, there is some debate over toothed vs smooth. My personal opinion is:

- I, and a few others, have had improvements from switching to authentic Gates brand pulleys and idlers. They are more expensive, but are worth it in my opinion.

Try printing the test objects ![]() here.

here.

Ensure that the artifacts are always vertical or diagonal, regardless of part geometry. These patterns can be subtle (lumps) or sharp (lines).

If the pattern looks like “wood grain”, or any of the example photos in that link, see ![]() this article instead.

this article instead.

-

Ensure that your A/B pulleys and XY joint idlers are all clean. Debris can accumulate and compress between the teeth.

- You may have a bad/poor quality pulley or toothed idler.

- See above section for more info / links.

- You may have a bad/poor quality bearing.

- Loosen the A/B belts, pull the belt over the side of each bearing flange, and turn each bearing by running it against your finger. Make sure the whole rotation feels smooth.

- You may have poor quality belts. Only use genuine Gates brand belts.

- You may have a bad/poor quality linear rail.

Narrowing it Down (CoreXY)

Print two wide square objects, one in normal orientation, and one at 45 degrees.

Inspect the object to see which axes the artifacts appear most prominent in.

(components in each section are in order of likelihood)

- Artifacts are equally prominent in all directions:

- A and B motor pulleys

- X and Y linear rails

- A and B belts

- A and B motors

- Artifacts are most prominent in in A:

- Bearings in A belt path

- A motor pulley

- A belt

- A motor

- Artifacts are most prominent in in B:

- Bearings in B belt path

- B motor pulley

- B belt

- B motor

- Artifacts are most prominent in in X:

- XY joint idlers

- X linear rails(s)

- Artifacts are most prominent in in Y:

- Y linear rails

- Artifacts are most prominent in in A/B/X, but not Y:

- XY joint idlers

- X linear rail(s)

- Artifacts are most prominent in in A/B/Y, but not X:

- Y linear rails

- Artifacts are most prominent in in X/Y, but not A/B:

-

A and B motors

- Certain motor models have been found to cause this when both are operating at the same time (i.e. X/Y moves)

- The following motor settings are passed around on the Voron Discord, and apparently can help in some cases (particularly with certain LDO motors on Voron V0). It may also help in other cases, worth a try.

-

A and B motors

# Set the below settings for both X AND Y motors, **in addition** to your current settings.

[stepper_x]

microsteps: 32

[tmc2209 stepper_x]

interpolate: false

stealthchop_threshold: 999999 # I'm not sure on this one. I tend to advise against using stealthchop (set to 0). Try both.

driver_TBL: 2

driver_TOFF: 2

driver_HEND: 1

driver_HSTRT: 4

driver_PWM_LIM: 8

driver_PWM_GRAD: 8

driver_PWM_FREQ: 1

driver_PWM_REG: 4