Lines Method (DEPRECATED)

![]() This page is compatible with Klipper and Marlin.

This page is compatible with Klipper and Marlin.

- You should

calibrate your extruder first.

Marlin: Linear advance must be

enabled in firmware. Not all printers have it enabled by default.

-

This has been deprecated in favor of my new pressure advance tuning tool! See

This has been deprecated in favor of my new pressure advance tuning tool! See  here.

here. -

The contents of this page may be out of date!

The contents of this page may be out of date!

Table of contents

Steps

-

Visit the

pressure advance calibration site.

pressure advance calibration site.- Thanks to Deuce#8801 for helping with this!

- If you are using

Marlin, use

Marlin, use  Marlin’s linear advance site instead.

Marlin’s linear advance site instead.

-

Fill out the parameters specific to your setup (printer name, bed size, retraction, etc.)

-

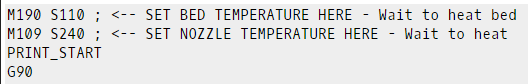

Modify the Start G-code section.

Exercise caution here. As mentioned previously, you can damage your printer if you don’t set up the start g-code correctly, for example forgetting

Exercise caution here. As mentioned previously, you can damage your printer if you don’t set up the start g-code correctly, for example forgetting QUAD_GANTRY_LEVELorPRINT_START(if used).- This is where you will set your temperatures (

M109/M190). - Copy over your slicer’s start g-code (from your printer profile) and paste it beneath the

M109/M190.- You can usually replace the default gcode beneath the

M109/M190with your own start g-code*, but use your best judgment. The defaults are there as safeguards. -

Klipper

- Stock

PRINT_START/START_PRINTmacros usually contain all the necessary start gcode (minus the temperatures), but please double check.- For Vorons with the stock

PRINT_STARTmacro, this is all you need: - If you are

passing variables to

passing variables to PRINT_START, remember to append them here. Example:PRINT_START HOTEND=240 BED=110- Your variable naming may be different, e.g.

EXTRUDER=Xinstead ofHOTEND=X. - You can then comment out the separate heating g-codes.

- Your variable naming may be different, e.g.

- For Vorons with the stock

- Stock

- Remove the

M112. This is an emergency stop / reading comprehension check to ensure you have reviewed the start gcode. - * If the start g-code from your slicer has any slicer variables (for example

[first_layer_bed_temperature]), make sure to replace them with appropriate values.

- You can usually replace the default gcode beneath the

- This is where you will set your temperatures (

-

Fill out the tuning parameters. Many can be left at defaults, but here are some specific settings that I recommend:

-

Printer

-

Layer Height: 0.2mm*

- *Or the primary layer height that you intend to print at. <0.2mm can make first layer difficult, however.

- *On textured beds, you may want to try 0.25mm to verify if your results are reading high (>0.06 PA on direct drive)

-

Layer Height: 0.2mm*

-

Speed

-

Slow Printing Speed: Your

square_corner_velocityFrom your printer.cfg. Default is 5.-

For Marlin, use your typical jerk value.

For Marlin, use your typical jerk value.

-

-

Fast Printing Speed: Your perimeter speed

- If your internal/external perimeter speeds are different, use the faster of the two.

-

See

See  this table to ensure that you are not exceeding the maximum flow rate of your hotend.

this table to ensure that you are not exceeding the maximum flow rate of your hotend. - The line widths refer to the “nozzle line ratio” option.

- Default is 1.2 (120%).

- The line widths refer to the “nozzle line ratio” option.

- *If your perimeter speeds are particularly slow, it may be hard to read the results. You may need to use a higher speed here in that case.

- Acceleration: Your perimeter acceleration

-

Slow Printing Speed: Your

-

Pattern

- Starting Value for PA: 0

-

Ending Value for PA:

- Direct Drive: 0.1

- Bowden: 1.5*

-

PA Stepping:

- Direct Drive: 0.005

- Bowden: 0.05*

-

Test Line Spacing:

- Voron 0 (120mm bed): 4

- Default: 5

- Print Anchor Frame: Checked

-

Advanced

- Nozzle Line Ratio: 1.2

- Prime Nozzle: Unchecked

- Dwell Time: 0

* These bowden values cover a wide range of PA (0-1.5), because each bowden setup can vary widely. Once you narrow down a general range to work in, you may want to run the test again with a narrower range of PA values.

-

Printer

-

Generate and download the g-code file.

-

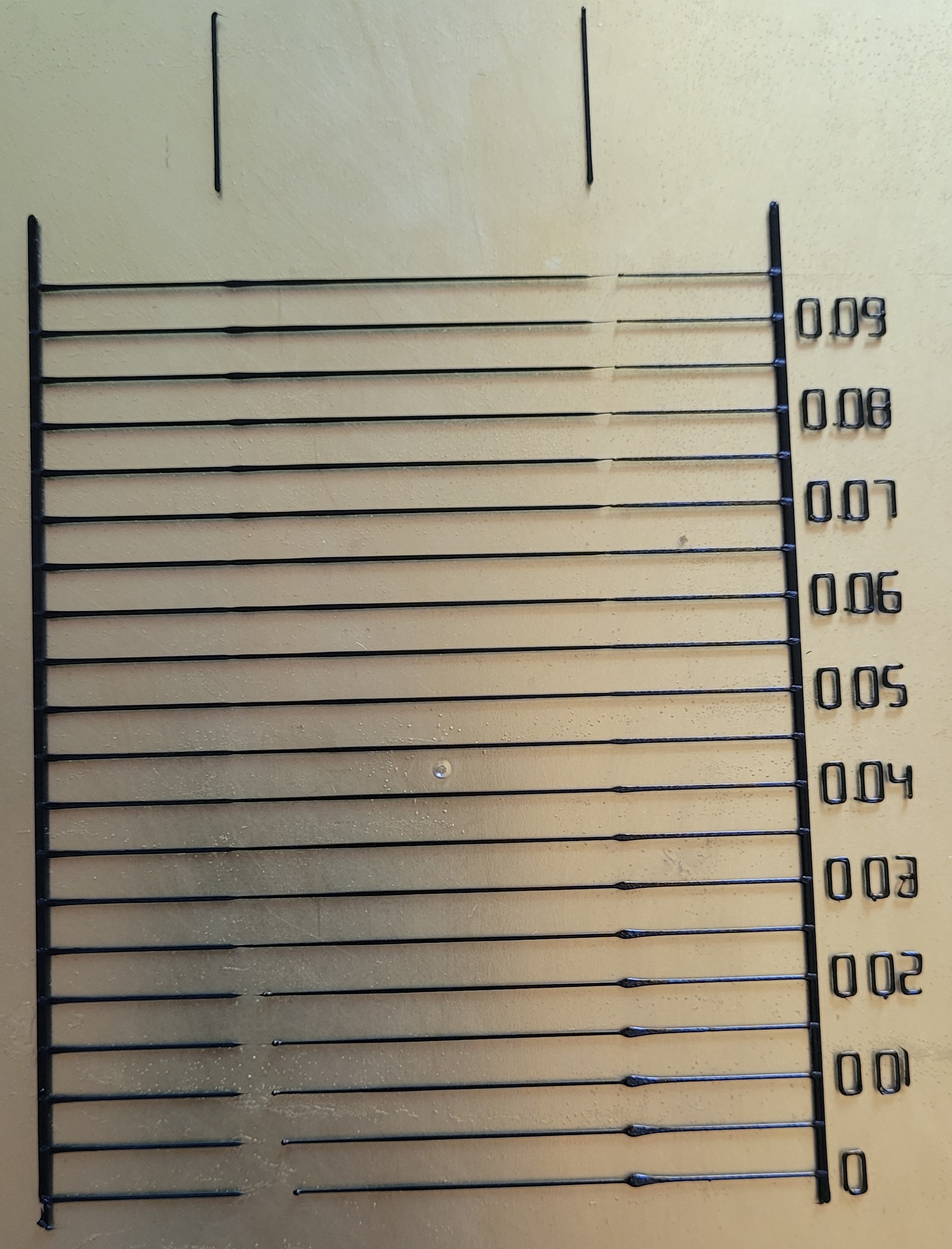

Print it, and inspect the results.

- In the below example, I would choose about 0.055.

Result

- This is a great visual representation of what I mentioned earlier: that pressure advance is rarely perfect.

- Always choose the lower value if you are not entirely sure.

- Sometimes the best acceleration and decelerations values will not be on the same line. In this case, you should pick a midpoint between both.

- If they are more than a line or two apart, see the next section.

- In the below example, I would choose about 0.055.

-

See

Saving Your Value.

Saving Your Value.

Anomalies / Issues

This PA test also serves as a nice extruder stress test, and it’s a great visual indicator for extrusion issues. It ensures that your extruder/hotend can handle your requested speeds, PA, and accelerations.

- If your best accel/decel PA values are more than a line or two apart:

- You may have too much

backlash in your extruder. Pressure advance uses a reverse extruder move during decelerations. Excessive backlash causes some of that reverse move to be lost.

backlash in your extruder. Pressure advance uses a reverse extruder move during decelerations. Excessive backlash causes some of that reverse move to be lost. - See

here for more information on the effects of backlash/gear tension.

here for more information on the effects of backlash/gear tension. - You still want a tiny amount of backlash (when filament is loaded) to ensure your extruder gears aren’t over tensioned. Essentially as little as you can manage.

- This is not adjustable on some extruders like the Orbiter (doesn’t have the same backlash issues anyway in my experience!)

- You may have too much

- If your PA numbers are unusually high:

- This may indicate a partial nozzle clog or that your hotend temperature is too low. More back pressure means more pressure advance.

- If the middle (fast) section is not printing, or is only partially printing:

- Your printer is having issues extruding at faster speeds. You may be outrunning your hotend, have your temperature too low / incorrect thermistor type in your config, have your extruder motor currents incorrect, have a partial clog, or have an extruder assembly issue. See

here for more in-depth troubleshooting.

here for more in-depth troubleshooting. - If this only happens above your ideal PA value, it’s not an issue.